Table of Contents

- 1. Introduction

- 2. Activated Carbon: VOC Adsorption and Subsequent Risks

- 3. Methodology for Analyzing Combustion Characteristics

- 4. Four Stages of Activated Carbon Combustion

- 5. Key Findings: Impact of VOCs on Combustion

- 6. Managing Combustion Risks of VOC-Loaded Activated Carbon

- 7. Conclusion

Introduction

Volatile organic compounds (VOCs) are major air pollutants contributing to smog and other environmental problems. Activated carbon is a widely used adsorbent for VOC removal, but VOC-loaded activated carbon poses potential fire and explosion hazards due to altered combustion characteristics. This article examines the impact of VOC adsorption on activated carbon’s combustion properties and provides safety recommendations.

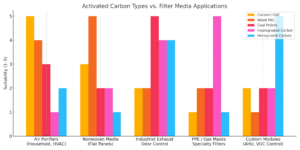

Activated Carbon: VOC Adsorption and Subsequent Risks

Activated carbon’s high surface area and porous structure make it effective for VOC adsorption. However, saturation with VOCs changes its combustion behavior, increasing the risk of spontaneous combustion and fires. Understanding these changes is crucial for safe handling and disposal of VOC-loaded activated carbon.

Methodology for Analyzing Combustion Characteristics

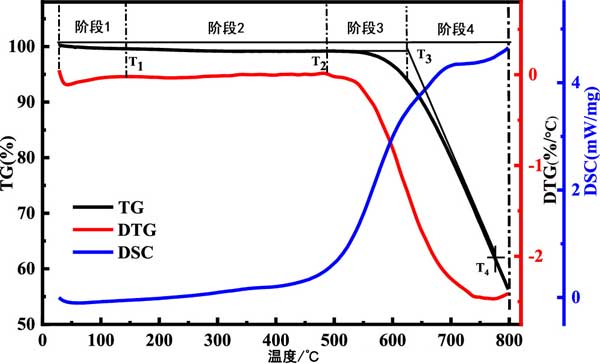

This study investigated the combustion characteristics of activated carbon before and after adsorbing common VOCs: acetone, cyclohexane, and butyl acetate. Thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and TG-FTIR were employed to analyze temperature changes, heat release, and gas emissions during controlled combustion. Samples were heated from 30°C to 800°C at 10K/min with a 15mL/min air flow.

Four Stages of Activated Carbon Combustion

The combustion of activated carbon, both with and without adsorbed VOCs, typically proceeds through four stages:

- 1. Water Evaporation and Desorption: Moisture and volatile compounds are released.

- 2. Oxygen Absorption and Weight Gain: Activated carbon reacts with oxygen, leading to a temporary weight increase and heat generation.

- 3. Thermal Decomposition: The carbon structure begins to break down, resulting in weight loss.

- 4. Combustion: Rapid oxidation occurs, releasing significant heat and potentially causing a flame.

VOC adsorption can significantly impact these stages, often leading to earlier desorption and contributing to faster ignition and increased heat release.

Key Findings: Impact of VOCs on Combustion

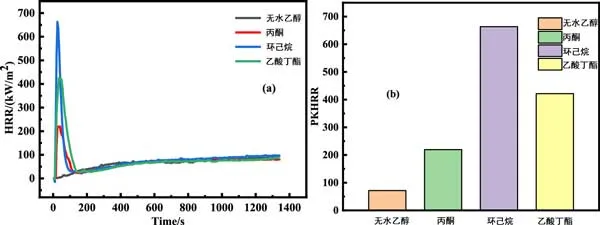

- – Faster Ignition: VOC-loaded activated carbon ignited more quickly than unloaded carbon, with cyclohexane-loaded samples exhibiting the fastest ignition.

- – Increased Combustion Intensity: VOCs, particularly cyclohexane, increased flame height and overall combustion intensity.

- – Higher Heat Release Rate (HRR): VOC adsorption significantly elevated the HRR, indicating a more rapid and intense combustion process. Cyclohexane showed the highest HRR.

- – Elevated Carbon Monoxide (CO) Yield: Combustion of VOC-loaded activated carbon produced higher CO levels, indicating a greater risk of toxic byproducts.

Managing Combustion Risks of VOC-Loaded Activated Carbon

This study highlights the significant changes in combustion characteristics of activated carbon after VOC adsorption. The increased risk of rapid ignition, higher heat release, and toxic byproduct formation necessitate careful handling and disposal of VOC-loaded activated carbon. Recommendations include:

- – Preventative Measures: Minimize VOC loading on activated carbon through optimized process control and regular carbon replacement.

- – Regular Thermal Analysis: Conduct periodic thermal analysis of activated carbon, especially in high-temperature environments, to assess potential combustion risks.

- – Controlled Storage: Store VOC-loaded activated carbon in cool, well-ventilated areas away from ignition sources.

- – Safe Disposal: Implement proper disposal procedures for VOC-loaded activated carbon, potentially including thermal treatment or incineration under controlled conditions.

Conclusion

Understanding the combustion behavior of VOC-loaded activated carbon is crucial for preventing fires and ensuring safe operation. By implementing the recommendations outlined in this article, industries can effectively manage the risks associated with VOC-adsorbed activated carbon and protect personnel and the environment.

Article Keywords: activated carbon, VOC adsorption, combustion, ignition, heat release rate, HRR, carbon monoxide, CO, thermal analysis, safety, risk management, VOC-loaded, cyclohexane, acetone, butyl acetate, self-ignition, fire hazard, explosion risk.