Honeycomb Activated Carbon Filters: Understanding Pressure Drop for Optimal Performance

Explore the main causes of pressure drop in honeycomb activated carbon filters. Learn how cell size, thickness, carbon density, and airflow affect industrial filtration performance.

Understanding RCO, CO, and RTO: Choosing the Right VOC Abatement Technology

Introduction Volatile Organic Compounds (VOCs) are significant air pollutants emitted from various industrial processes, including chemical manufacturing, painting, and petrochemical refining. Controlling VOC emissions is critical not only for regulatory compliance but also for environmental sustainability and workplace safety. This blog explores three leading VOC abatement technologies—Regenerative Catalytic Oxidizer (RCO), Catalytic Oxidizer (CO), and Regenerative […]

How to Calculate Activated Carbon Fill Volume for VOCs Treatment: A Practical Guide for Industrial Clients

Learn how to calculate the correct activated carbon fill volume for VOCs treatment systems. Discover expert design tips, replacement cycles, troubleshooting, and cost analysis.

Selecting and Replacing Activated Carbon for Optimal Industrial Exhaust Gas Treatment

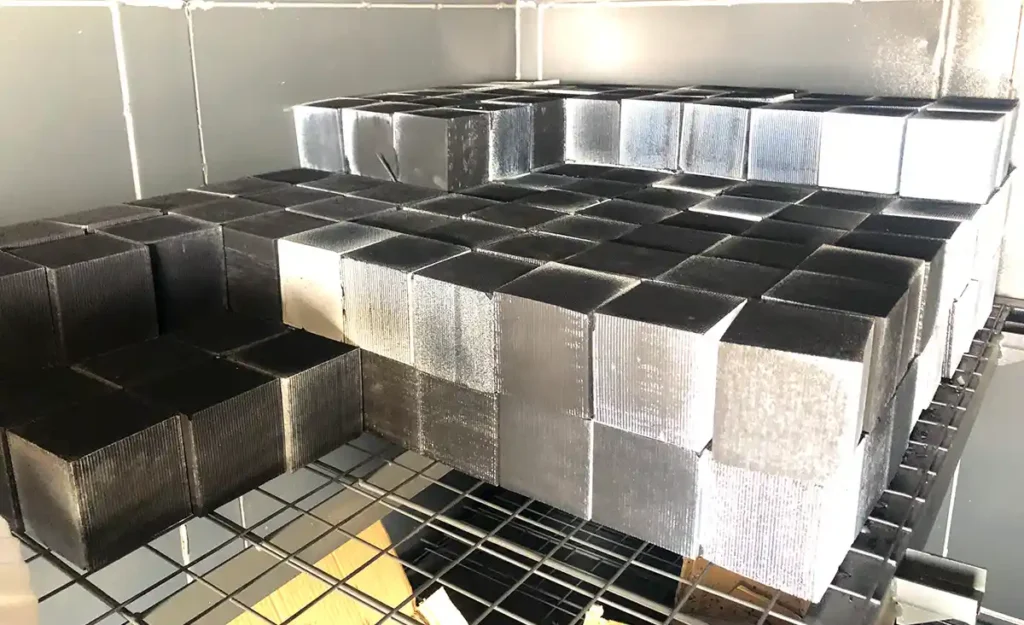

Activated carbon plays a vital role in industrial exhaust gas treatment by adsorbing VOCs and harmful pollutants. This article explains the two most commonly used types—honeycomb activated carbon and columnar activated carbon—highlighting their advantages and disadvantages. It also provides a practical guide on how to estimate replacement cycles based on VOC loads and discusses common pitfalls during carbon replacement. By following the outlined best practices, industries can improve gas purification efficiency, extend system life, and ensure compliance with environmental regulations.

How to Store Activated Carbon Safely for Peak Performance

This article explains the importance of proper activated carbon storage and outlines four critical precautions: keep it dry, avoid contamination, ensure fire safety, and protect against moisture. Improper storage can lead to reduced efficiency, spontaneous combustion, and increased operational costs. By understanding how to store activated carbon correctly, businesses can maintain product quality, reduce waste, and optimize performance in industrial applications such as water treatment, air purification, and gas filtration.

Why Two-stage VOCs Treatment is Essential for Effective Pollution Control

This article explores the critical need for two-stage or combined treatment processes for volatile organic compounds (VOCs), demonstrating the limitations of single-stage treatments. It highlights the numerous advantages and practical applications of dual-stage activated carbon adsorption as a highly effective two-stage treatment solution.

Why 5 Single VOC Treatment Methods Limited: The Power of Integrated Solutions

This article discusses 5 commonly used but inefficient VOCs treatment technologies: photooxidation, photocatalysis, low-temperature plasma, single-use activated carbon adsorption, and spray absorption. Understand their limitations and discover why combining multiple methods is the key to achieving stable and efficient VOC removal.

Activated Carbon: Effective SO2 Removal from Humid Exhaust Gases

Activated carbon demonstrates excellent performance in SO2 removal from both dry and humid exhaust gases, and it is a valuable material for industrial desulfurization.

VOC-Loaded Activated Carbon: Understanding and Managing Combustion Risks

Understanding the combustion behavior of VOC-loaded activated carbon is crucial for preventing fires and ensuring safe operation, industries can effectively manage the risks.

Beyond Iodine Value: Optimizing Activated Carbon Specification for VOC Adsorption

Table of Contents Introduction Activated carbon is a versatile adsorbent widely employed in environmental applications, particularly for capturing volatile organic compounds (VOCs). While iodine value is a commonly used metric to assess activated carbon’s performance, it’s essential to consider other factors to ensure optimal adsorption efficiency. This article explores the key metrics influencing activated carbon’s […]