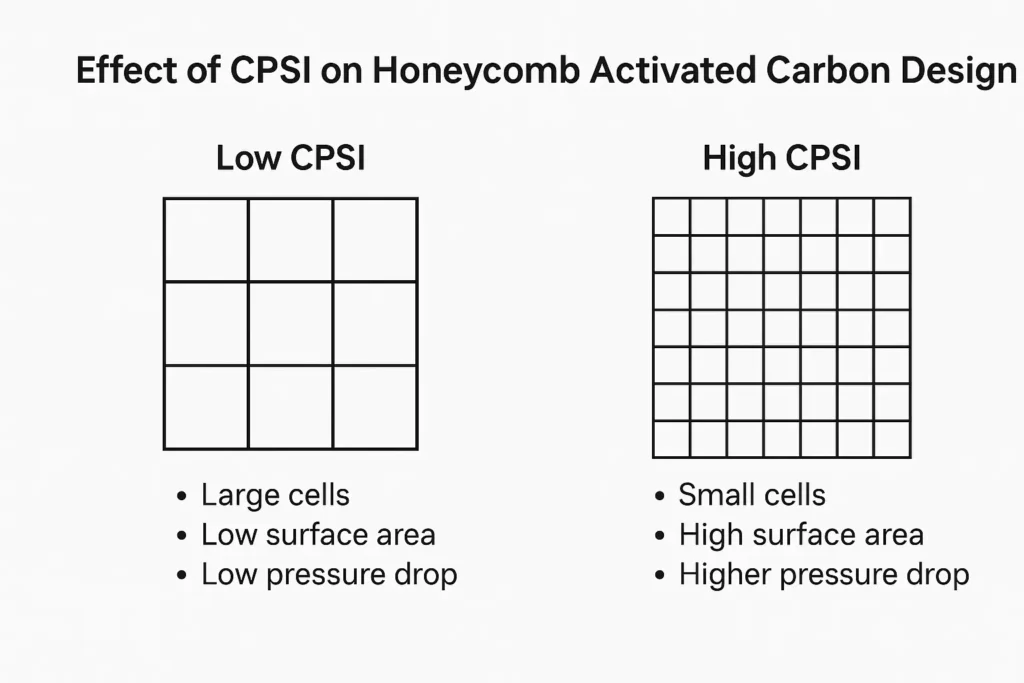

Why CPSI Alone Cannot Define Honeycomb Activated Carbon Performance

This article explains why CPSI (cells per square inch) should not be treated as a standalone performance indicator for honeycomb activated carbon filters. By examining airflow behavior, contact time, adsorption kinetics, and carbon utilization, it highlights the limitations of CPSI-only comparisons and provides a more practical engineering perspective for industrial gas-phase filtration design.

Design Considerations for Honeycomb Activated Carbon Filters in Industrial Systems

This article explains the essential design considerations for honeycomb activated carbon filters used in industrial equipment, including material selection, CPSI, adsorption efficiency, airflow direction, pressure drop, sealing, frame compatibility, and maintenance planning.

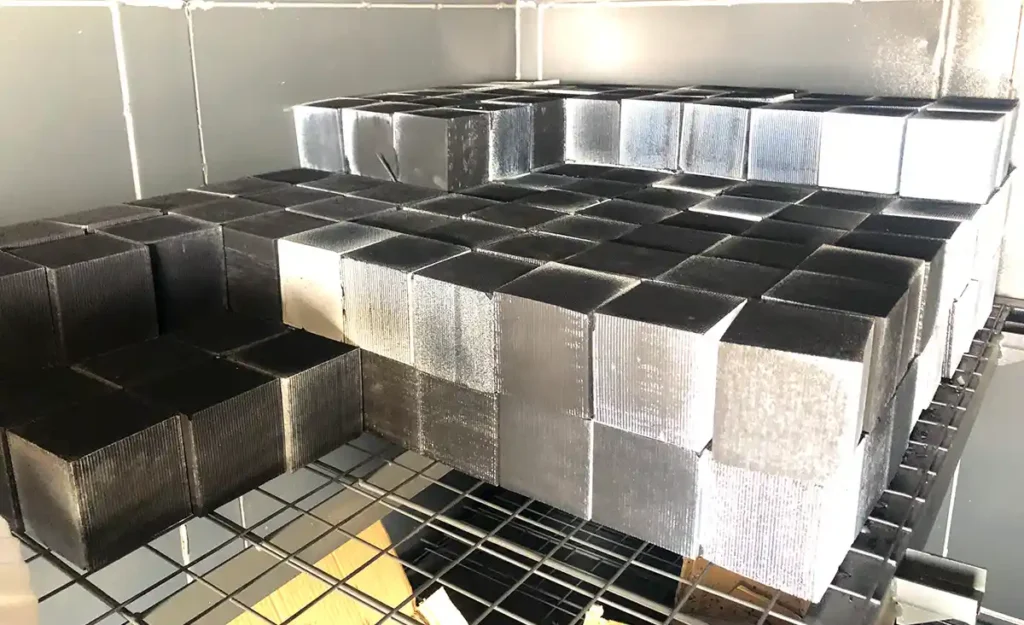

How Many Honeycomb Activated Carbon Blocks Loaded in a Container? A Practical Loading Guide

This guide explains how many honeycomb activated carbon blocks can be loaded into 20GP and 40HQ containers using standard packing data. It also covers half-height sizes, custom dimensions, pallet calculations, and protective packaging for small trial shipments.

The Role of Honeycomb Activated Carbon in VOC Control Systems | HANYAN

A practical guide to designing and operating VOC control systems with honeycomb activated carbon – covering mechanisms, parameters, applications, regeneration, and integration best practices.

Sustainable Air Filtration: How Honeycomb Activated Carbon Supports Carbon Neutral Goals

Honeycomb activated carbon offers an eco-friendly solution for industrial air purification by combining high adsorption efficiency with low energy consumption and recyclability – helping industries move closer to carbon-neutral goals.

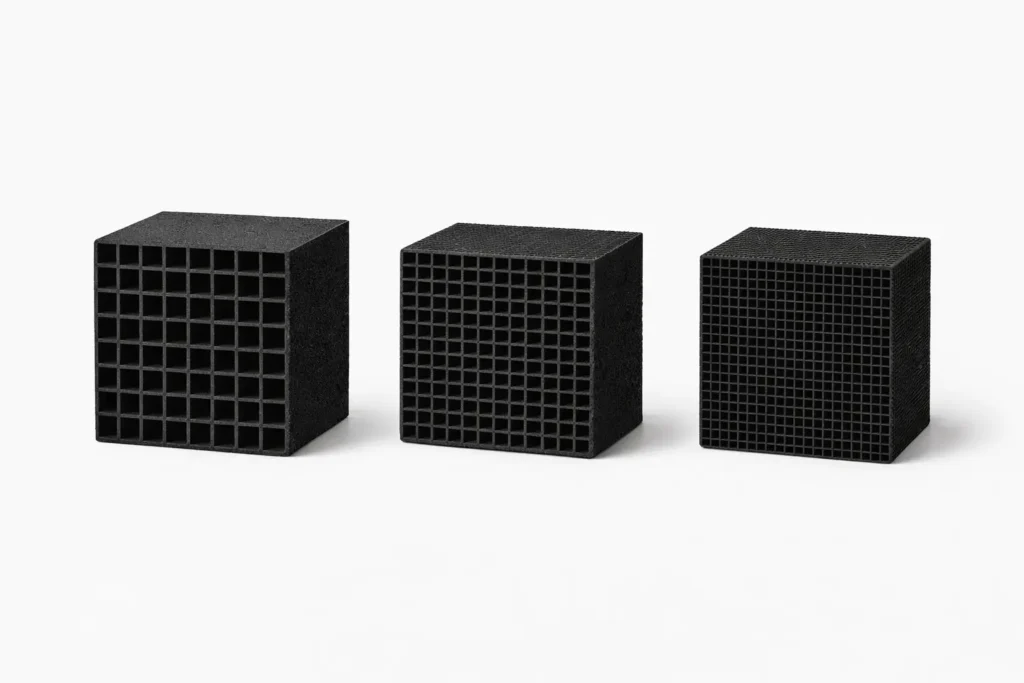

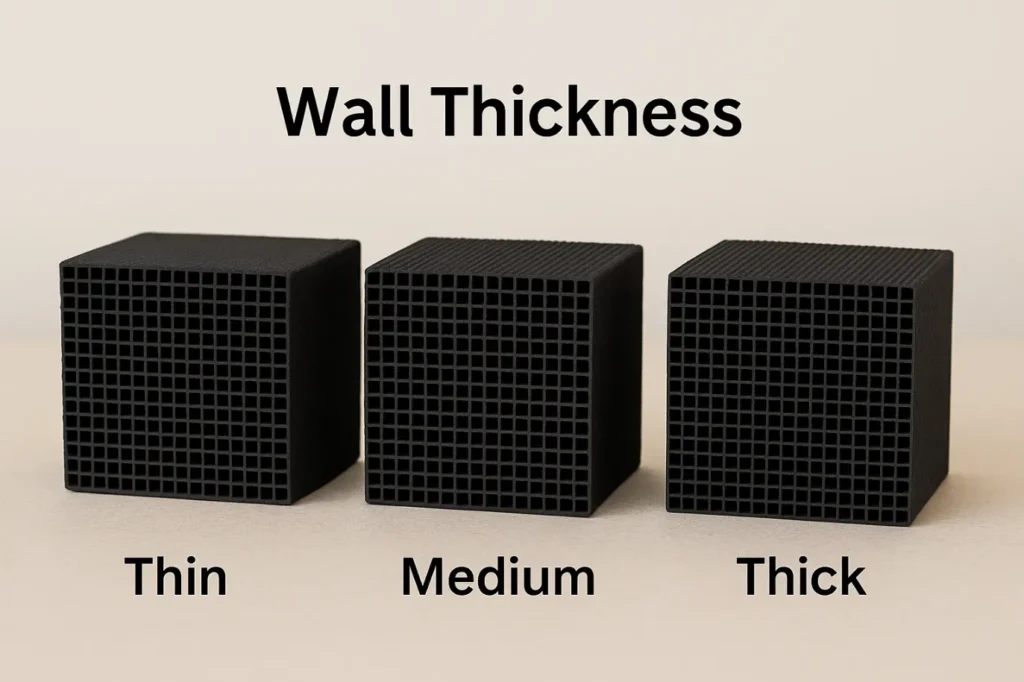

Why Wall Thickness Matters in Honeycomb Activated Carbon Filters

Learn why wall thickness is critical in honeycomb activated carbon filters. Improve airflow, efficiency, and filter lifespan by choosing the right design parameters.

How to Choose the Right CPSI for Honeycomb Activated Carbon

CPSI (Cells Per Square Inch) is a critical design factor for honeycomb activated carbon filters. This article explores how CPSI impacts airflow resistance, adsorption efficiency, and mechanical strength, and provides practical guidelines for selecting the optimal structure for different applications.

World’s First: HANYAN CTC≥85% Honeycomb Activated Carbon

HANYAN launches a new generation of honeycomb activated carbon with a CTC adsorption rate ≥85%, setting a new global benchmark in VOC control. Backed by 3,000+ lab experiments, this product offers unmatched adsorption efficiency, improved regeneration performance, and longer service life – making it a top-tier solution for industrial air filtration.

How to Calculate Activated Carbon Fill Volume for VOCs Treatment: A Practical Guide for Industrial Clients

Learn how to calculate the correct activated carbon fill volume for VOCs treatment systems. Discover expert design tips, replacement cycles, troubleshooting, and cost analysis.

Selecting and Replacing Activated Carbon for Optimal Industrial Exhaust Gas Treatment

Activated carbon plays a vital role in industrial exhaust gas treatment by adsorbing VOCs and harmful pollutants. This article explains the two most commonly used types—honeycomb activated carbon and columnar activated carbon—highlighting their advantages and disadvantages. It also provides a practical guide on how to estimate replacement cycles based on VOC loads and discusses common pitfalls during carbon replacement. By following the outlined best practices, industries can improve gas purification efficiency, extend system life, and ensure compliance with environmental regulations.