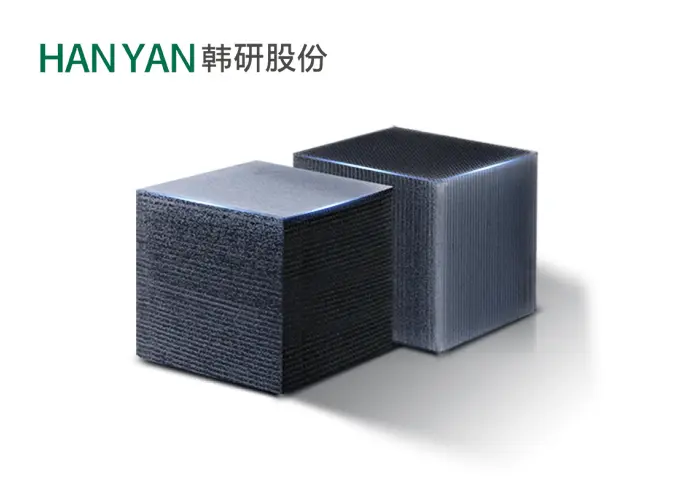

World’s First: HANYAN CTC≥85% Honeycomb Activated Carbon

HANYAN launches a new generation of honeycomb activated carbon with a CTC adsorption rate ≥85%, setting a new global benchmark in VOC control. Backed by 3,000+ lab experiments, this product offers unmatched adsorption efficiency, improved regeneration performance, and longer service life – making it a top-tier solution for industrial air filtration.

Selecting and Replacing Activated Carbon for Optimal Industrial Exhaust Gas Treatment

Activated carbon plays a vital role in industrial exhaust gas treatment by adsorbing VOCs and harmful pollutants. This article explains the two most commonly used types—honeycomb activated carbon and columnar activated carbon—highlighting their advantages and disadvantages. It also provides a practical guide on how to estimate replacement cycles based on VOC loads and discusses common pitfalls during carbon replacement. By following the outlined best practices, industries can improve gas purification efficiency, extend system life, and ensure compliance with environmental regulations.

Activated Carbon: Effective SO2 Removal from Humid Exhaust Gases

Activated carbon demonstrates excellent performance in SO2 removal from both dry and humid exhaust gases, and it is a valuable material for industrial desulfurization.

Purifying Propane Emissions with Activated Carbon Adsorption

Activated carbon adsorption emerges as a powerful tool for capturing and removing propane emissions, safeguarding both the environment and industrial operations.

Activated Carbon Adsorption for Aluminum Refinery Exhaust Treatment

Activated carbon adsorption is highly effective in gas treatment, making it a promising technology for reducing emissions from aluminum refineries.

Activated Carbon Treatment of Emissions in Small Appliance Factories

Activated carbon used for treating emissions from small appliance factories is a sustainable method to reduce environmental issues in production processes.

Service Life of Activated Carbon in Gas Adsorption Treatment

Careful consideration of the characteristics of the airflow and the design of the activated carbon bed makes gases adsorption treating a highly efficient pollution control.