Honeycomb Production Material

The production of honeycomb activated carbon is quite different from coal/wood/coconut activated carbon and more complicated. It uses qualified activated carbon powder and binder as raw material, processing formed after high temperature activation together.

Because of the production technology limit, though using iodine 1000mg/g qualified activated carbon powder as raw material, iodine adsorption value of the finished honeycomb will also be greatly reduced to 40-60% of the original one.

At present, the highest limit of iodine adsorption value of products that can be mass-produced in the entire honeycomb activated carbon industry across China can only reach 600mg/g.

Normal Market Iodine

Iodine 500: Iodine 500-600 may be the best one you can find in the market for steadily mass production, not so many factories can produce it.

Iodine 300: Iodine 300-400 is very common in the market, most factories can produce it.

Iodine 100: Iodine 100-200 is also existing and widely needed in the market, but obviously the adsorption capacity is very low.

HANYAN R&D

As a leading honeycomb manufacturer, HANYAN has already produced and sold iodine 500-600 honeycomb activated carbon for long time, and our R&D team is still committed to developing higher quality honeycomb activated carbon.

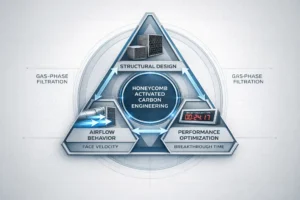

Another important specification for honeycomb: CTC

Except for iodine value, CTC is another very important specification for honeycomb activated carbon. Actually iodine value is an important specification in liquid phase adsorption while CTC(carbon tetrachloride) is normally used in gas phase adsorption. Honeycomb activated carbon is widely used for vapor treatment, CTC should be a more proper specification to judge the adsorption performance.

At present, HANYAN is the first manufacturer to produce CTC 65% honeycomb activated carbon in China, 1cbm honeycomb carbon can adsorb about 100-120kg/m³ VOCs.