Introduction

Volatile Organic Compounds (VOCs) are significant air pollutants emitted from various industrial processes, including chemical manufacturing, painting, and petrochemical refining. Controlling VOC emissions is critical not only for regulatory compliance but also for environmental sustainability and workplace safety.

This blog explores three leading VOC abatement technologies—Regenerative Catalytic Oxidizer (RCO), Catalytic Oxidizer (CO), and Regenerative Thermal Oxidizer (RTO)—and helps you determine which is best suited for your operational needs.

Understanding VOC Abatement Technologies

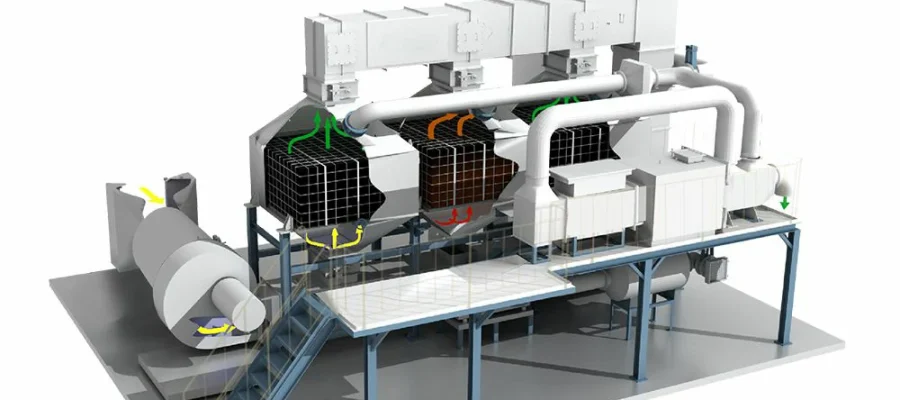

1. Regenerative Catalytic Oxidizer (RCO)

Mechanism:

RCO systems combine catalytic oxidation with regenerative heat recovery. They use catalysts to oxidize VOCs at relatively low temperatures (250–350°C), making them energy-efficient. Mainly applied with activated carbon for adsorption and catalyst for catalyzing.

Advantages:

- High thermal efficiency (>95%)

- Lower fuel consumption

- Effective removal rates (95–99%)

Limitations:

- Catalyst deactivation due to poisoning or fouling

- Higher initial cost

- Not ideal for VOCs containing sulfur, halogens, or nitrogen compounds

Best Applications:

Industries with moderate VOC loads looking for energy efficiency and high removal performance.

2. Catalytic Oxidizer (CO)

Mechanism:

CO systems rely on catalysts to facilitate VOC oxidation at lower temperatures, but they do not incorporate heat recovery systems.

Advantages:

- Lower operational temperatures (~250–350°C)

- Reduced fuel costs

- Compact and easy to install

Limitations:

- Moderate VOC destruction efficiency (80–90%)

- Limited by catalyst lifespan and cost

- Not suitable for varying or low VOC concentrations

Best Applications:

Processes with steady VOC concentrations and spatial constraints.

3. Regenerative Thermal Oxidizer (RTO)

Mechanism:

RTOs use high temperatures (760–820°C) to oxidize VOCs and feature regenerative heat exchangers that recover energy from the exhaust.

Advantages:

- Very high VOC destruction efficiency (>99%)

- Excellent thermal recovery (>90%)

- Ideal for high air volume operations

Limitations:

- Higher operational costs

- Larger equipment footprint

- Susceptible to clogging with self-polymerizing VOCs

Best Applications:

Facilities with large airflows and dilute VOC concentrations.

Comparative Analysis

| Feature | RCO | CO | RTO |

|---|---|---|---|

| Operating Temp | 250–350°C | 250–350°C | 760–820°C |

| Thermal Efficiency | >95% | Moderate | >95% |

| Destruction Efficiency | High | Moderate to High | Very High (>99%) |

| Fuel Consumption | Low | Low | Higher |

| Catalyst Use | Yes | Yes | No |

| Heat Recovery | Yes | No | Yes |

| Capital Cost | High | Moderate | High |

| Maintenance Needs | Moderate | Moderate | High |

Selecting the Right Technology

When selecting the optimal VOC abatement solution, consider the following:

- VOC Characteristics: Concentration, composition, and volume

- Operational Requirements: Energy efficiency, available space, and budget

- Environmental Compliance: Emission standards and regulations

Recommendations:

- RCO is best for operations with stable VOC profiles and a focus on low energy costs.

- CO suits facilities needing a compact and cost-effective solution for consistent VOC levels.

- RTO is ideal for high-volume airflows and demanding removal efficiency standards.

Conclusion

Selecting the right VOC abatement system—RCO, CO, or RTO—is crucial for industrial efficiency, regulatory compliance, and environmental stewardship. Each technology offers distinct advantages and should be evaluated based on specific application needs. Consult with air treatment professionals to assess your VOC profile and operational goals for the best outcomes.

FAQs

Q1: What factors influence the choice between RCO, CO, and RTO?

VOC concentration, airflow rate, catalyst sensitivity, and cost considerations.

Q2: How does catalyst deactivation affect RCO and CO systems?

Deactivated catalysts lower efficiency and increase maintenance costs.

Q3: Can RTO systems handle varying VOC concentrations?

Yes, especially effective for large volumes with low VOC levels.

Q4: Are there environmental considerations?

Yes, including emissions, fuel use, and potential NOx generation.

Q5: What is the lifespan of these systems?

Typically 10–15 years with regular maintenance.

Article Keywords: VOC abatement technologies, Regenerative Catalytic Oxidizer, Catalytic Oxidizer, Regenerative Thermal Oxidizer, RCO vs RTO vs CO, industrial air pollution control, VOC removal efficiency, best VOC treatment system, air quality control solutions, emissions reduction technology