Honeycomb activated carbon, a versatile material used in various industries such as air purification and gas treatment, is renowned for its exceptional adsorption capabilities. A key performance parameter for honeycomb activated carbon is the carbon tetrachloride index (CTC). This article explores the CTC index, its significance, and the measurement process, offering valuable insights for industrial applications.

Table of Contents:

- The Carbon Tetrachloride Index: A Measure of Adsorption Performance

- The Importance of the CTC Index

- Measuring the CTC Index: A Step-by-Step Guide

- Conclusion

1. The Carbon Tetrachloride Index: A Measure of Adsorption Performance

The CTC index quantifies the adsorption capacity of honeycomb activated carbon for carbon tetrachloride (CCl₄), a volatile organic compound (VOC). A higher CTC index indicates superior adsorption efficiency, making it a crucial metric for evaluating activated carbon’s suitability in applications requiring VOCs removal. CTC is generally used as an specification of the adsorption capacity of activated carbon for VOCs gases. In some places, the butane adsorption index is used for similar effect.

How is the CTC index calculated?

- The CTC index is obtained by exposing honeycomb activated carbon to carbon tetrachloride vapor at controlled temperature and pressure. The amount of carbon tetrachloride gas adsorbed is measured and compared to the weight of the honeycomb activated carbon sample, which provides the CTC index.

2. The Importance of the CTC Index

The CTC index is an essential parameter for determining the performance of honeycomb activated carbon in industrial applications. It serves several important functions:

- Predicts adsorption efficiency: A high CTC index suggests excellent performance in removing VOCs and other pollutants.

- Guides material selection: Manufacturers can use the CTC index to select appropriate raw materials and production processes for specific applications.

- Enhances product quality: By optimizing the CTC index, manufacturers can create high-performance honeycomb activated carbon products.

3. Measuring the CTC Index: A Step-by-Step Guide

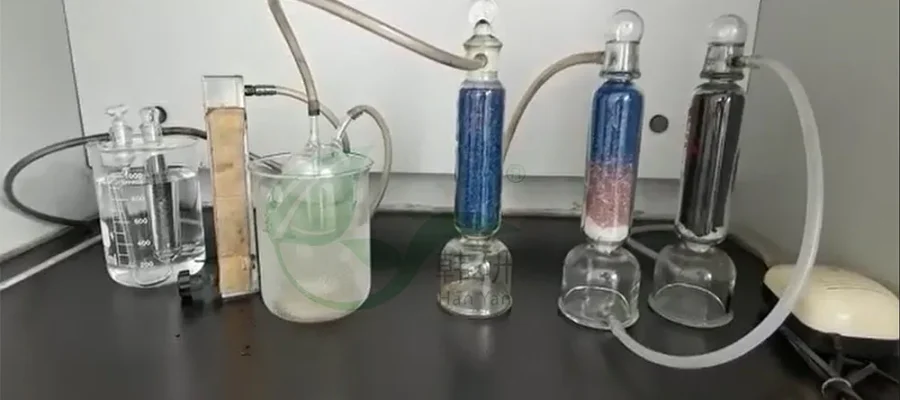

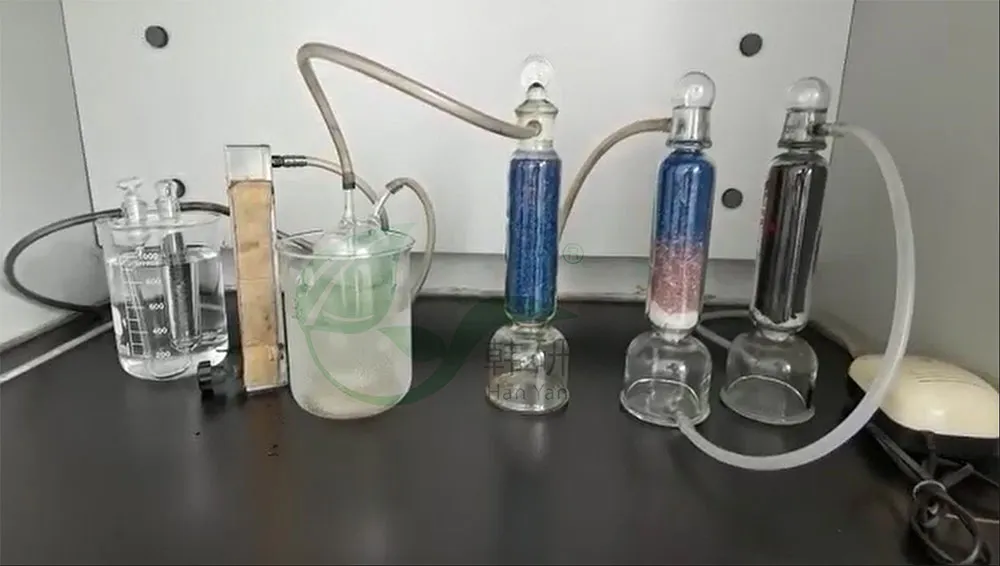

The measurement process for the CTC index involves several steps, detailed below:

Equipment and Materials:

- Honeycomb activated carbon sample

- Carbon tetrachloride (CCl₄)

- Crucibles, drying oven, balance scale, test tube, weighing paper, etc.

Test procedure:

- Sample Preparation: Obtain a dry sample of honeycomb activated carbon and measure its mass (m₁).

- Vapor Exposure: Expose the sample to carbon tetrachloride vapor under controlled conditions.

- Adsorption Measurement: Determine the mass of adsorbed carbon tetrachloride (m₄).

- CTC Index Calculation: Use the formula: CTC index = [(m₄ – m₁) / m₁] × 100%

4. Conclusion

Generally, honeycomb activated carbon with CTC above 40% is regarded as a good product, and the CTC of honeycomb activated carbon produced by HANYAN can reach up to 75%, which is one of the highest indexes of honeycomb activated carbon in China. In practical application, you can choose the honeycomb activated carbon products with appropriate adsorption performance according to different application fields and needs.

The carbon tetrachloride index is a vital parameter for assessing the performance of honeycomb activated carbon in industrial applications. By understanding the CTC index and its measurement process, manufacturers and users can make informed decisions regarding activated carbon selection and optimization.

Keywords: honeycomb activated carbon, carbon tetrachloride index, CTC index, adsorption capacity, VOC removal, air purification, water treatment, industrial applications, activated carbon measurement, surface area, pore structure, activated carbon production