Honeycomb activated carbon combines a high geometric surface area with straight, low-resistance channels – delivering strong VOC adsorption at exceptionally low pressure drop. This article explains how honeycomb activated carbon works, how to size and select it (CPSI, iodine value, CTC), and where it outperforms other media in coating lines, printing factories, electronics, chemical plants, and etc.

Contents

- How Honeycomb Activated Carbon Captures VOCs

- Key Design Parameters (CPSI, Iodine, CTC, ΔP)

- Typical Applications and Industry Use Cases

- Service Life, Breakthrough & Regeneration

- System Integration Tips

- Common Pitfalls & How to Avoid Them

- FAQs

How Honeycomb Activated Carbon Captures VOCs

Honeycomb activated carbon is an extruded block with thousands of channels. VOC-laden air passes through straight passages, contacting carbon walls with abundant micro/mesopores.

- High Mass Transfer:

Thin walls + straight flow paths reduce boundary layers and promote rapid adsorption. - Low Pressure Drop:

Compared with packed granular beds, HAC often cuts ΔP by 30–60% at the same face velocity. - Uniform Flow:

Monolithic structure minimizes bypassing and channeling common in loose-fill beds. - Modularity:

Blocks stack into cassettes for easy scale-up and quick replacement.

Key Design Parameters (CPSI, Iodine, CTC, ΔP)

| Parameter | Typical Range | Notes |

|---|---|---|

| CPSI (cells/in²) | 100–400 | Lower CPSI lowers ΔP; higher CPSI increases contact area. Common choices: 100–300 CPSI. |

| Wall thickness | 0.3–1.0 mm | Thinner walls aid mass transfer; consider strength and dusting. |

| Iodine number | 500–1100 mg/g | Proxy for micropore volume; match pore distribution to VOC size (mesopores for aromatics/resins). |

| Face velocity | 0.3–1.5 m/s | Balance between efficiency and ΔP; verify with pilot tests. |

| CTC | 40-85 | Higher CTC for highly adsorbable VOCs in gas control. |

| SV (space velocity) | 3,000–8,000 h⁻¹ | Selected per VOC spec and outlet target; check breakthrough curves. |

Tip: For mixed VOCs, choose a blended pore structure or staged beds (front layer targeting larger molecules; back layer for lighter solvents).

Typical Applications and Industry Use Cases

- Coating & Painting Lines: Adsorption of toluene, xylene, MEK; ideal as a stand-alone polisher or as a pre-step to thermal oxidation.

- Printing & Packaging: Captures ethyl acetate, alcohols from gravure/flexo presses with minimal ΔP, lowering fan energy.

- Electronics & Semiconductors: Removal of photoresist solvents, amines, acid gases (with impregnated grades).

- Chemicals & Adhesives: Abatement for mixed aromatics/ketones; modular cassettes simplify maintenance.

- Laboratories & Pilot Plants: Point-of-use polishing for vents and hoods without large infrastructure.

Mini Case Benchmarks (illustrative)

| Industry | VOC | Design (CPSI / EBCT) | ΔP | Outcome |

|---|---|---|---|---|

| Auto paint | Toluene/Xylene 150–300 mg/m³ | 200 CPSI / 0.6 s | < 180 Pa | >90% removal; fan energy ⬇ vs. GAC bed |

| Printing | Ethyl acetate 200 mg/m³ | 300 CPSI / 0.45 s | < 150 Pa | Odor complaints eliminated |

| Electronics | MEK/IPA mix 120 mg/m³ | 150 CPSI / 0.8 s | < 160 Pa | Stable outlet < 20 mg/m³ |

Service Life, Breakthrough & Regeneration

Service life depends on inlet concentration, humidity, temperature, and purge strategy. Monitor using outlet VOC sensors and scheduled sampling.

- Breakthrough definition: Outlet reaches 5–10% of inlet (site-specific).

- On-site regeneration: Warm purge gas or low-temp steam can desorb many solvents.

- Off-site reactivation: For heavily loaded media or mixed solvents.

- Swing operation: Dual beds allow adsorption/regeneration cycling to maximize uptime.

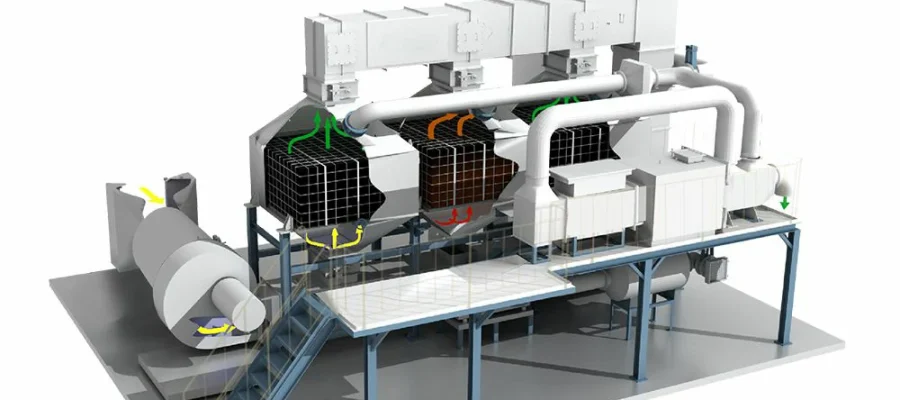

System Integration Tips

- Pre-filtration: G4–F7 filters prevent dust fouling; consider mist eliminators for oil aerosols.

- Sealing & Bypass: Use gasketed cassettes; check compression to avoid channel edge leakage.

- Instrumentation: ΔP gauges, RH/temperature, and outlet VOC sensors for predictive maintenance.

- Safety: Bonding/grounding; avoid ignition sources; evaluate LEL at high solvent loads.

- Hybrid systems: HAC polishing after RTO/RCO reduces odors and achieves ultra-low emissions.

Common Pitfalls & How to Avoid Them

- Under-sized EBCT: Leads to early breakthrough. Validate with pilot tests.

- No humidity control: High RH competes for pores—install dehumidification if needed.

- Poor sealing: Bypass flow defeats adsorption. Use proper frames and gaskets.

- Incompatible VOC mix: Consider impregnated or customized pore distributions.

- Neglected ΔP monitoring: Rising ΔP signals fouling—check pre-filters and loading.

FAQs

1.How does honeycomb compare with granular carbon beds?

A: Honeycomb provides similar removal at much lower pressure drop, resists channeling, and is easier to install as modular blocks. Granular beds can offer higher ultimate capacity for very long EBCTs but need deeper vessels and stronger fans.

2.Can I use HAC for acid gases?

A: Yes, with impregnated grades (e.g., alkaline or oxidizing impregnants) for HCl, SO₂, or low-level NOx/amine odors.

3.What maintenance schedule is recommended?

- Monthly: check ΔP and leakage;

- Quarterly: sampling for outlet VOC;

- Annually: review breakthrough trends and replace/regen plan.

Need help sizing a honeycomb activated carbon system?

HANYAN engineers can calculate EBCT/SV, predict breakthrough, and match CPSI & pore structure to your VOC profile.

- Standard grades: 150–400 CPSI, iodine 800–1100

- Impregnated options for acid/alkaline gases

- Custom cassettes and frames for quick retrofit

Article Keywords: honeycomb activated carbon, VOC control, gas phase filtration, EBCT, space velocity, low pressure drop, adsorption, regeneration, CPSI