Ⅰ.Overview

With the growing severity of domestic air pollution problems, various places across the country have successively introduced and implemented the Air Pollution Prevention Action Plan and taken a series of measures, such as strengthening publicity and guidance during inspections, issuing commitment letters to enterprises, urging waste-producing plants to strictly fulfill their pollution prevention responsibilities, and beginning to collect VOCs emission fees from chemical and other chemical enterprises.

Currently, in terms of industrial waste gas VOC control, there are mainly physical, chemical, and biological methods, including adsorption, direct combustion, catalytic combustion, chemical oxidation, biological filter ponds, and other treatment methods. The adsorption method is currently recognized as a treatment method with high efficiency, wide applicability, simple operation, and low investment and operating costs. And Activated Carbon is known as a universal adsorbent, playing a crucial role in the control of VOC waste gas by adsorption.

Ⅱ.Indentification of High-Quality Activated Carbon

Recently, there are quite a few platforms pushing the “guide” for the selection of activated carbon. So, as a national specialized and innovative “Little Giant” company specializing in the research, production, and sales of activated carbon, let’s take a look together with HANYAN to see if these “guides” are really applicable?

No.1: Look?

Opinion 1:

The smaller the particles of activated carbon, the larger the contact area with air, and the better the adsorption effect. It is suggested not to buy activated carbon with particles over 2mm. The smaller the particles of activated carbon, the larger the specific surface area, and the better the adsorption effect.

HANYAN’s Analysis:

1. Under the same adsorption index conditions, the smaller the particle size of the columnar activated carbon (the smaller the honeycomb through-hole), the larger the contact area; plus the larger wind resistance and the longer contact time; indeed, under the same conditions, the adsorption effect will be more ideal. However, if the particle size is too small and the wind resistance is too large, it will cause high operation costs. Therefore, the current majority of project conditions prefer to use 4mm pellet activated carbon, the claim that it is not recommended to choose activated carbon over 2mm is incorrect. Moreover, the adsorption quality of activated carbon cannot be judged by looking at the particle size.

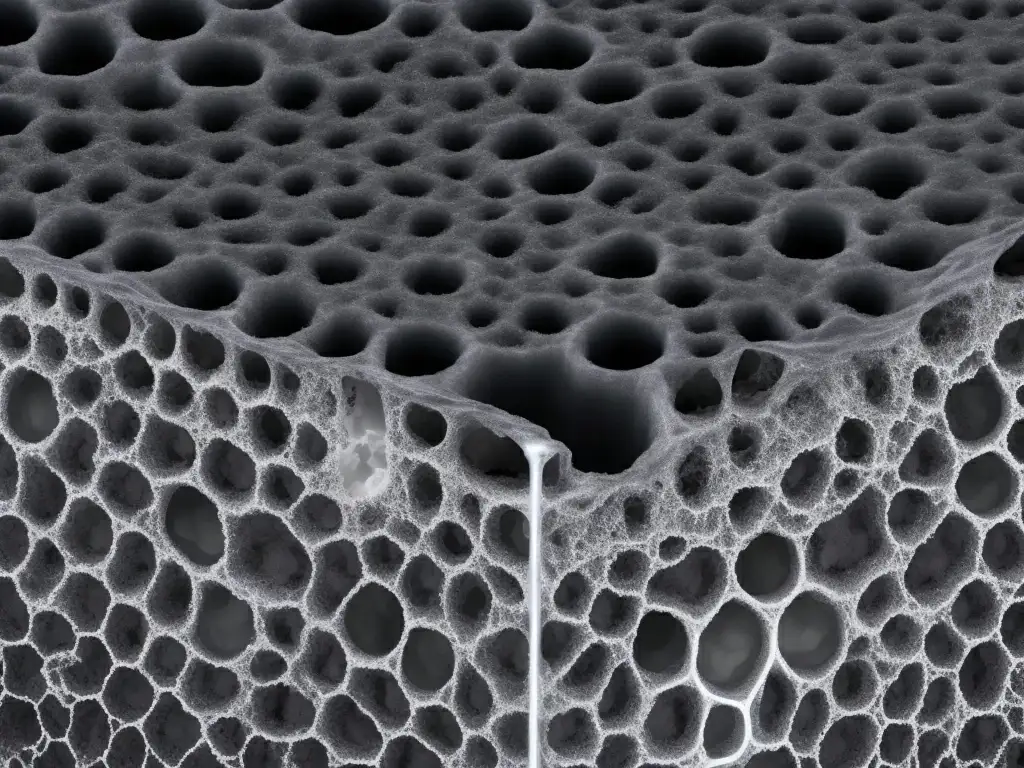

2. The specific surface area usually refers to the internal surface area of activated carbon. During the activation of activated carbon, pores of different shapes and sizes are generated between the microcrystals, and the internal surface area is the sum of the surface areas of all the pores, which is an important indicator to measure the adsorption ability of activated carbon. This index value needs to be obtained through the specific surface area analyzer, and it cannot be judged by the naked eye.

3. So when can we see the quality of activated carbon through appearance? Some activated carbon, indeed by appearance, can be judged to be of extremely poor quality. For example, if the particles are large, long and curved, the color is grayish, or even rust-colored, the surface of the particles is pitted, etc. If we see this type of activated carbon when purchasing, we should pay more attention.

No.2: Touch?

Opinion 2:

In the production process of activated carbon, the dust produced by activated carbon will be dealt with. At present, inferior activated carbon on the market, in order to reduce costs, greatly reduces the hardness, and does not remove the dust from the activated carbon, so it will produce a lot of fine powder and heavy dust when rubbing against each other.

HANYAN’s Analysis:

The dust and ash in activated carbon, in professional terms, is called floating ash, which can be felt by touch. The external floating ash can be dealt with by screening, sieving, etc., to reduce its surface floating ash. Like the principle of “looking,” although most of the inferior activated carbon has more dust and high-quality activated carbon has less dust, it does not mean that the carbon with less dust has a higher adsorption capacity. High-quality activated carbon will have a slight amount of floating ash on the surface. Low-quality activated carbon can be cleaned by repeated sieving, but this method cannot improve the adsorption effect of activated carbon.

No.3: Weigh?

Opinion 3:

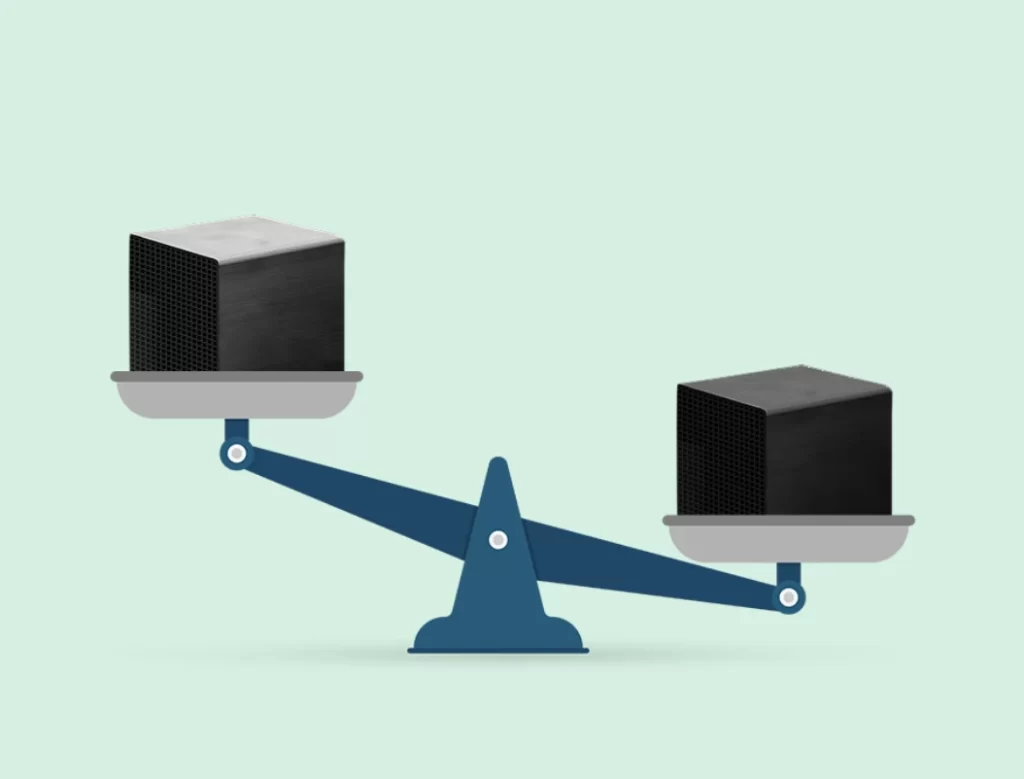

The higher the adsorption capacity of activated carbon, the more pores it has, making it more crumbly, and thus, lighter in relative density. Therefore, good activated carbon will be lighter, and under the same weight packaging, good quality activated carbon will have a much larger volume than inferior activated carbon.

HANYAN’s Analysis:

The principle that the stronger the adsorption capacity of activated carbon, the lighter the bulk density, is generally correct, but not rigorous enough. If you need to compare the bulk density, it needs to be based on the same material, shape, and production process of activated carbon. For example, a)under the same adsorption value and material conditions, the bulk density of granular activated carbon is different from powdered activated carbon; b)under the same adsorption value and shape, different materials have different bulk densities; c)even under the same adsorption value, the same shape, the same material, but different production processes may also result in different bulk densities.

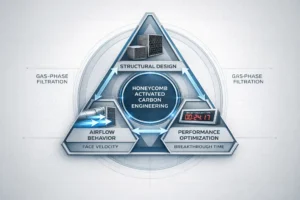

The bulk density of honeycomb activated carbon is greatly related to the raw material, mold, and production process. Currently, honeycomb activated carbon technology is mainly divided into HANYAN technology and Traditional technology. HANYAN technology mainly improves the overall porosity by adjusting the distribution ratio of nanopores, thereby truly enhancing the adsorption capacity by reducing the bulk density. However, the traditional molding process entirely relies on the wall thickness of the mold to reduce the density, and the actual adsorption quality has not been improved.

No.4: Experiment?

Opinion 4:

Observe the Bubbles:

Drop a small handful of activated carbon into water. Due to the permeation of water, it will gradually seep into the pore structure of the activated carbon, forcing the air in the pores to be expelled, thereby generating a series of extremely tiny bubbles, pulling out a thin line of bubbles in the water and making a “hissing” bubble sound. The more intense this phenomenon, and the longer it lasts, the better the adsorption of activated carbon. On the contrary, inferior activated charcoal sinks quickly, discontinuously, lasts relatively short, and may not even have bubbles or “hissing” sounds.

HANYAN’s Analysis:

The bubble test is somewhat referential but lacks rigor. The bubble comparison also needs to be based on the same material, the same process, and observed under the same moisture content of the activated carbon. Moreover, the number of bubbles can’t intuitively represent the adsorption effect.

Opinion 5:

Test Decolorization Ability:

Activated carbon has a special ability to turn colored liquids into light or colorless. You can try it with a small sample. Take two bright cups, put pure water in one, then drop a drop of red ink (any pigment that can be easily inspected which does not change the nature of the water, such as blue ink, printer color ink, but excluding ink and carbon ink). After mixing evenly, pour half of the colored water into the other cup for comparison. Put activated carbon into the colored water, the amount should be more than half of the water, then the effect will be noticeable. After standing for 10-20 minutes, compare it with the control water sample. Under the same conditions, the stronger the decolorization effect, the better the adsorption of activated carbon.

HANYAN’s Analysis:

The indicators representing the adsorption ability of activated carbon for different substances are not the same, mainly depending on the matching degree between the pore size of activated carbon and the molecular size of the adsorbed substance. The decolorization ability mentioned in the opinion usually represents the adsorption ability of activated carbon for pigment molecules. The methylene blue adsorption value or caramel decolorization rate is usually used as the characteristic index of liquid adsorption decolorization. Therefore, using the decolorization ability of activated carbon as a judgment method for VOCs adsorption ability is unscientific.

Note: In gaseous adsorption, the carbon tetrachloride adsorption rate in activated carbon should be paid attention to, the higher it is, the larger the VOCs adsorption volume is.

In conclusion, the quality of activated carbon is related to many indicators. It cannot be judged solely by one index by eyes.

Ⅲ.Quality Assessment About Activated Carbon

To accurately judge the quality of activated carbon, the most objective and scientific method is testing. As many regulatory authorities and users currently lack of testing capabilities, several commonly adopted measures are:

A. Commission authoritative institutions for testing:

Commission qualified institutions to test the purchased activated carbon according to relevant national standards, and provide corresponding test reports. This method is not only time-consuming but also costly, not all companies will implement it.

B. Test reports provided by suppliers:

Test reports provided by suppliers are usually divided into two types: one is the factory inspection report, and the other is the third-party inspection report.

- For factory inspection reports, it is necessary to consider whether the supplier has testing equipment and capabilities (it is recommended to inspect on-site);

- For third-party inspection reports, it is necessary to determine whether the report batch is consistent with the actual delivered products.

Given the uncertainty of the above two measures, HANYAN now offer FREE testing services to all customers, and warmly invite all new and old customers to visit our company on-site for guidance.

Ⅳ.The Need for Regulatory and User Capacity Building

A.Current Limitations

ATTENTION! There is now a high level of attention to VOCs management in various regions. Extracting the provisions of Article 108 of the Air Pollution Prevention Law of the People’s Republic of China, industrial coating companies that have not used low-volatility organic compound coatings or have not established and kept account books; production and service activities that generate volatile organic compound waste gas, have not installed and used pollution prevention facilities as required; are ordered by the ecological environment departments of the people’s government at the county level or above to correct and are fined; or the company faces the order to stop production for rectification.

B.Solutions

All companies should attach great importance to the management of VOCs. It’s important to choose the right activated carbon product in VOCs management, but it’s also crucial to choose the right activated carbon supplier, which is the core of the management.

Ⅴ.HANYAN: A Leader in Activated Carbon Industry

A.Company Overview

Guangdong HanYan Activated Carbon Technology Co., Ltd. (hereinafter referred to as HANYAN), is a national high-tech enterprise mainly engaged in the research and development, production, and sales of high-end activated carbon, a new environmental protection material. It is the leading company in the Chinese activated carbon subdivision industry, the leading company in the activated carbon industry in Guangdong Province, and a national-level specialized, refined, and special “Little Giant” enterprise.

HANYAN emphasizes the inclusion of “carbon peaking and carbon neutrality” into the overall strategic layout of the enterprise, committed to innovation in environmental protection new materials, and achieving a win-win situation across the entire industry chain. Since its establishment, the company and its holding subsidiaries have actively participated in city, province, and national key research and development plan projects, participated in the compilation of various activated carbon-related group and industry standards, and have their own enterprise standards. Currently, the company has a total of 135 patents, including 45 invention patents, and has been honored with the title of “Guangdong Province Intellectual Property Demonstration Enterprise”.

B.Offering Free Test Services

1.HANYAN Technical Equipment

HANYAN has two major testing bases, equipped with advanced testing equipment, a senior technical team, and experienced activated carbon R&D experts. With cutting-edge international technology leading the industry trend, it helps the environmental protection industry achieve high-quality development.

2.Test Items:

| Density | Iodine Value | Iron | Mesh Size |

| Moisture | pH | Chloride | Effective Size |

| Ash | Hardness | Heavy Metal | Pore Size Distribution |

| Methylene Blue | Carbon Tetrachloride | Sulphated Ash | Uniformity Coefficient |

| Caramel | Specific Surface Area | Water-soluble Substance | Particle Size Distribution |

3.How to Request Free Testing

Please prepare sample as stated below:

- Sample States: brand new, unused products, sealed package

- Quantity: More than 200g in quantity (quantity required depends on test items)

- Normal Schedule: about 3-5 working days

If you want to know the quality of your purchased activated carbon or required the most suitable quote, please feel free to consult us.