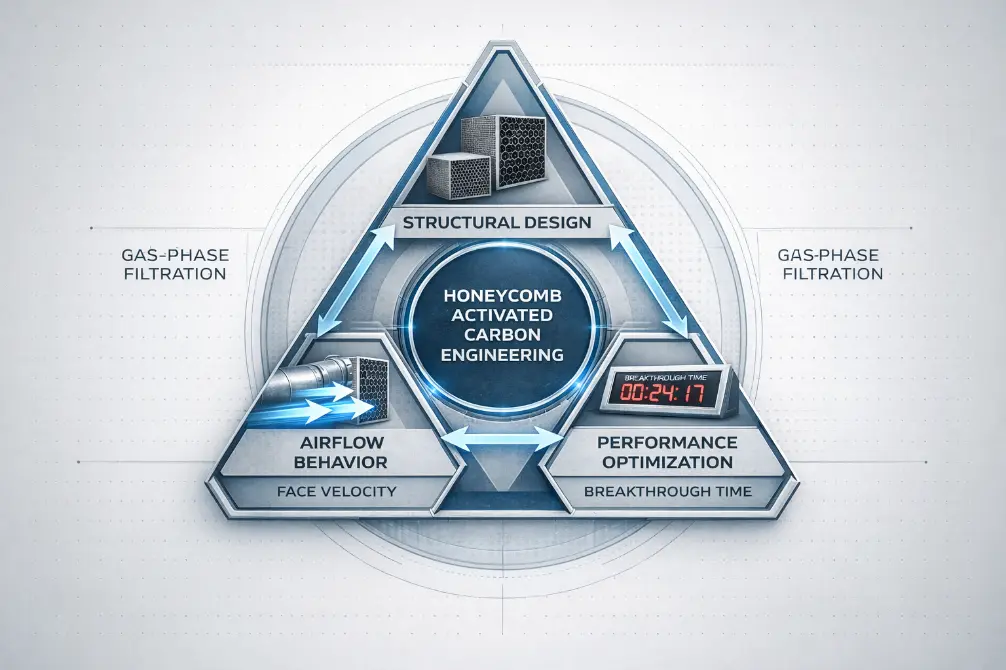

Honeycomb Activated Carbon Engineering Guide

This engineering guide consolidates key technical principles behind honeycomb activated carbon performance, including airflow resistance, CPSI, contact time, and breakthrough behavior. Designed for industrial gas-phase filtration professionals, it provides a structured framework for system-level evaluation and optimization.

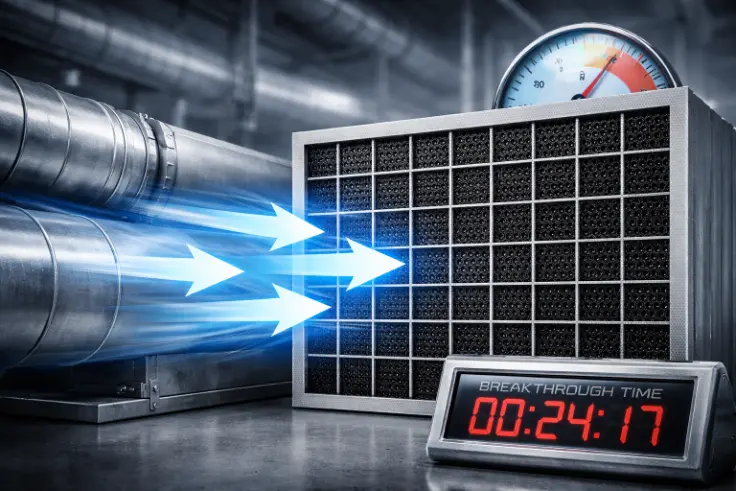

How Face Velocity Determines Breakthrough Time in Honeycomb Activated Carbon Filters

This article explains how face velocity influences breakthrough time in honeycomb activated carbon filters. It examines the relationship between airflow rate, contact time, adsorption kinetics, and carbon utilization, providing an engineering-level perspective for industrial gas-phase filtration design.

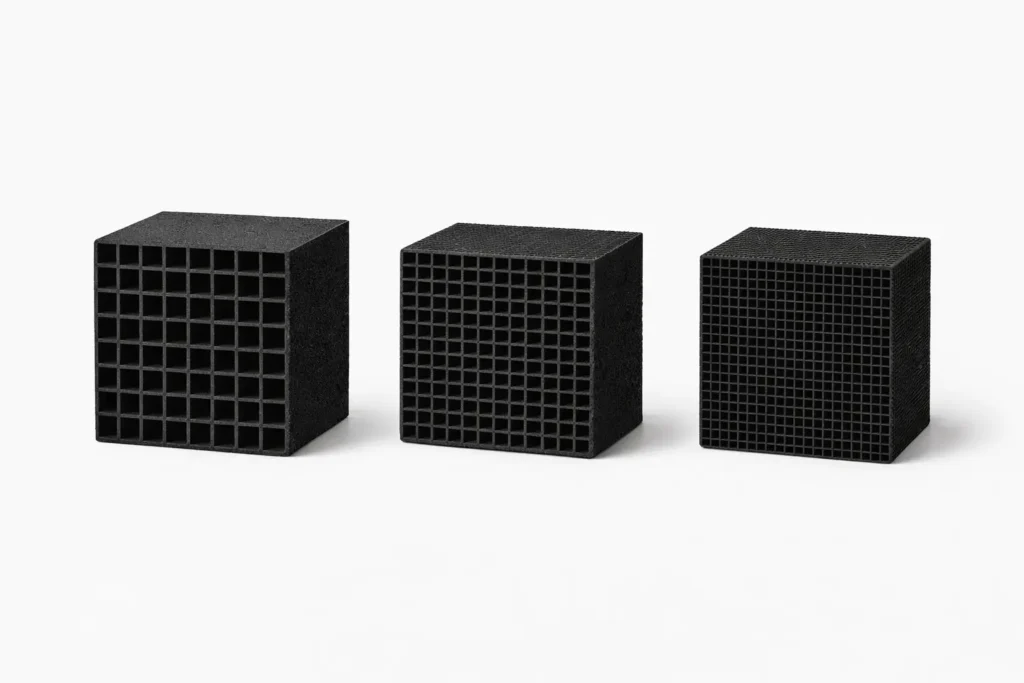

Why CPSI Alone Cannot Define Honeycomb Activated Carbon Performance

This article explains why CPSI (cells per square inch) should not be treated as a standalone performance indicator for honeycomb activated carbon filters. By examining airflow behavior, contact time, adsorption kinetics, and carbon utilization, it highlights the limitations of CPSI-only comparisons and provides a more practical engineering perspective for industrial gas-phase filtration design.

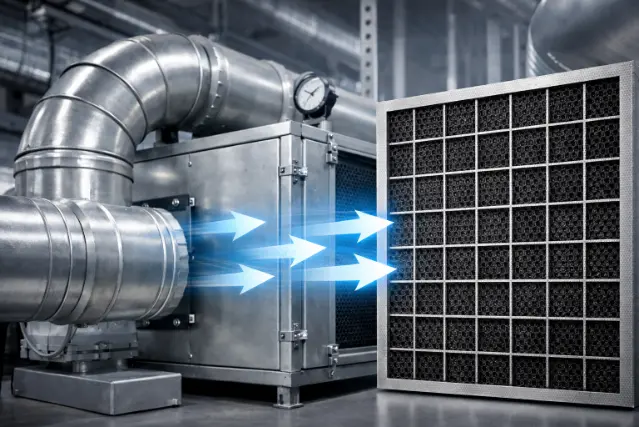

Pressure Drop vs Adsorption Performance in Honeycomb Activated Carbon Filters

This article explains the engineering relationship between pressure drop and adsorption performance in honeycomb activated carbon filters. It clarifies why very low resistance can reduce contact time and carbon utilization, leading to earlier breakthrough. Practical guidance is provided to help engineers balance fan energy, airflow velocity, and adsorption kinetics for application-specific performance.

Design Considerations for Honeycomb Activated Carbon Filters in Industrial Systems

This article explains the essential design considerations for honeycomb activated carbon filters used in industrial equipment, including material selection, CPSI, adsorption efficiency, airflow direction, pressure drop, sealing, frame compatibility, and maintenance planning.

How Many Honeycomb Activated Carbon Blocks Loaded in a Container? A Practical Loading Guide

This guide explains how many honeycomb activated carbon blocks can be loaded into 20GP and 40HQ containers using standard packing data. It also covers half-height sizes, custom dimensions, pallet calculations, and protective packaging for small trial shipments.

The Role of Honeycomb Activated Carbon in VOC Control Systems | HANYAN

A practical guide to designing and operating VOC control systems with honeycomb activated carbon – covering mechanisms, parameters, applications, regeneration, and integration best practices.

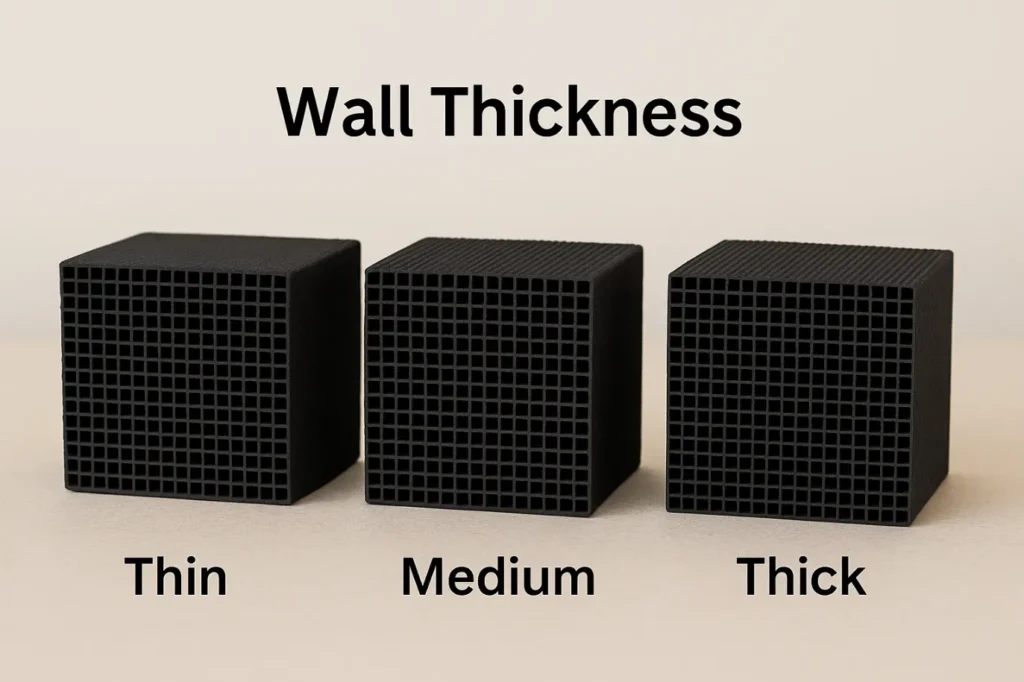

Why Wall Thickness Matters in Honeycomb Activated Carbon Filters

Learn why wall thickness is critical in honeycomb activated carbon filters. Improve airflow, efficiency, and filter lifespan by choosing the right design parameters.

How to Improve Filter Lifespan Using Impregnated Honeycomb Carbon

Impregnated honeycomb carbon filters offer superior performance for targeted gas removal. Learn how different impregnation types boost filter lifespan and how to choose the best solution for your application.

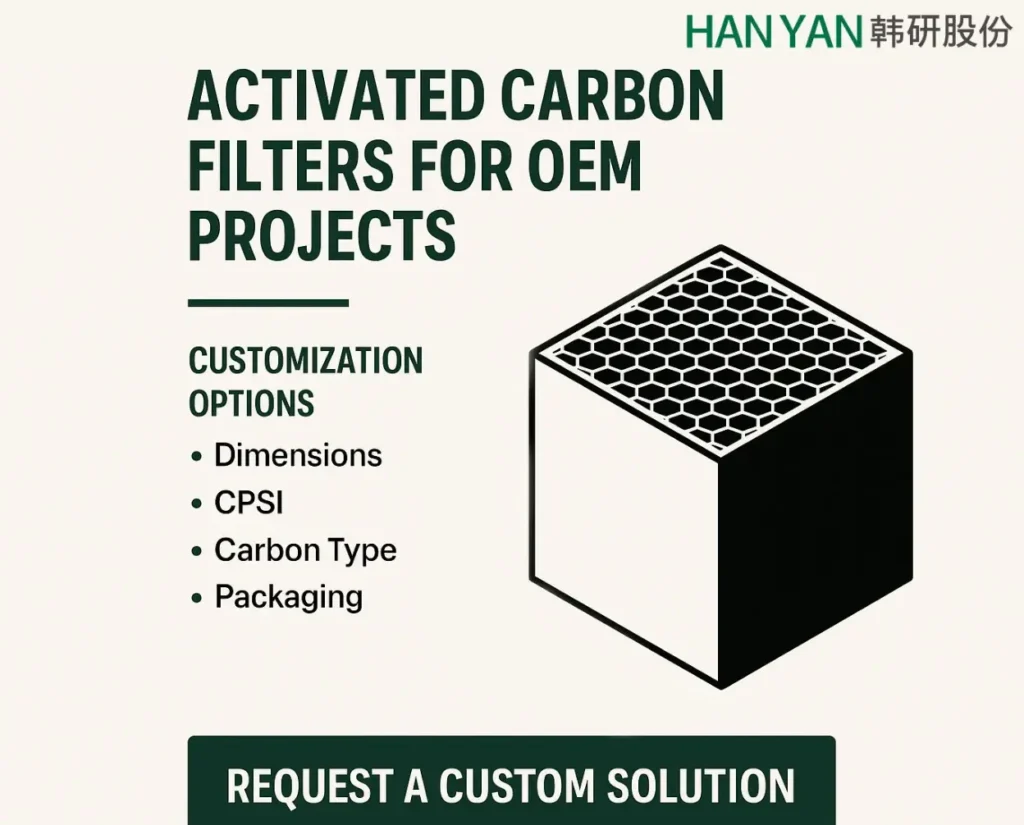

Custom Honeycomb Activated Carbon Filters for OEM Projects

OEM customers across industries are increasingly turning to honeycomb activated carbon filters for reliable VOC control, odor removal, and air purification. This article explains how HANYAN helps customize honeycomb carbon filters to meet project-specific performance, design, and regulatory needs – from size and cell density to activation process and packaging.