What is honeycomb activated carbon?

Introduction:

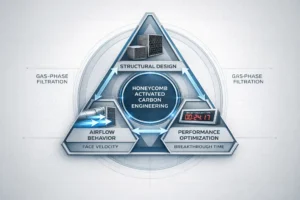

This product uses qualified activated carbon powder as raw material, processing formed after high temperature activation together. For its cellular appearance, it has been called honeycomb activated carbon.

Features:

It has relatively large contact area, developed microporous structure, high adsorption capacity, the biggest characteristic of it is small wind resistance.

Kinds:

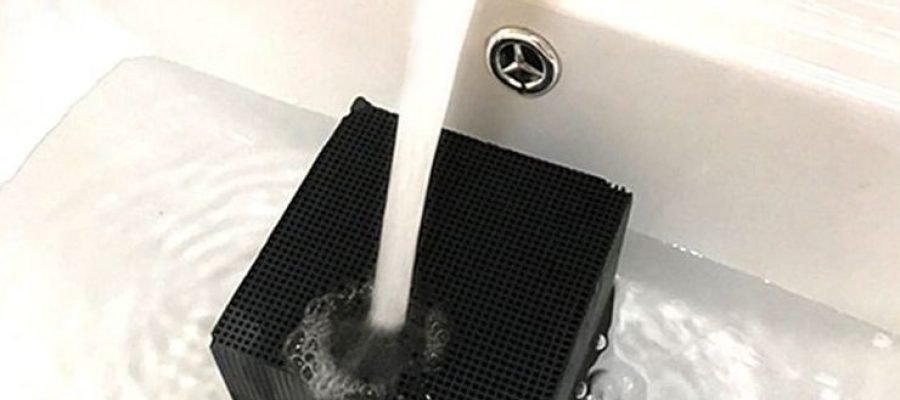

Products can be divided into two kinds: water proof and no water proof(normal kind).

Difference between water-proof and normal kind

Production Process:

Normal kind: Dry by air naturally.

Water-proof: Dry by air naturally, then need for further drying in the kiln under high temperature for several hours.

Delivery time:

Water-proof honeycomb activated carbon need about 5-7 days more than normal one, the production time will be longer in peak season.

Price:

Higher production cost leads to higher price than normal one.

Honeycomb activated carbon applications

It is widely used for vapor treatment especially VOCs removal. For example, it is used in industrial exhaust gas treatment, spray-paint room, airport, shipyard, electronics industry, automobile factory, pharmaceutical, medical, industrial building, large theater and other public places for gas treatment of ventilation equipment.

When should use water-proof kind?

Vapor Treatment:

- High humidity gas. When the humidity of waste gas is high and over 20%, normal honeycomb will be easily chalk and break, water-proof can avoid these conditions. If want to use normal kind to save cost, it should add drying process before the carbon.

- System with water spray device. Some systems will install water spray device for warning to avoid burning risk under high temperature, it should use water-proof kind.

Liquid Treatment:

Aquarium. Honeycomb activated carbon is popular to used in aquarium for purification, for this application, it must use water-proof kind.

Generally speaking, when the condition with high humidity and water contact possibility, it is recommended to use water-proof honeycomb activated carbon.