Why Low Resistance Does Not Always Mean Low Efficiency

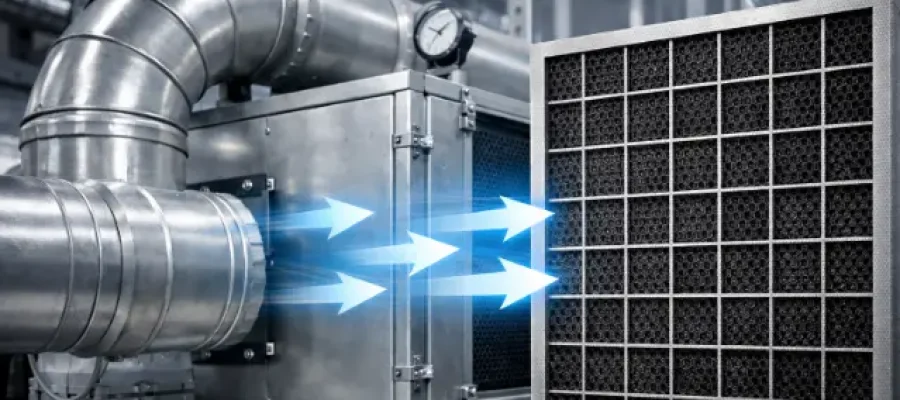

Honeycomb activated carbon filters are widely applied in industrial gas-phase filtration systems for VOC control, odor removal, and chemical adsorption. During system design and procurement, pressure drop is often discussed as a key indicator. However, treating resistance as a “performance score” can be misleading—because pressure drop mainly reflects airflow behavior, while adsorption performance depends on contact time, mass transfer, and pore utilization.

This article explains the engineering relationship between pressure drop and adsorption performance in honeycomb activated carbon filters, and clarifies why “lower resistance” does not always mean “better filtration.”

1. What Pressure Drop Really Means in Honeycomb Filters

Pressure drop refers to the loss of static pressure as air passes through the honeycomb channels. It is primarily influenced by:

- Cell density (CPSI – cells per square inch)

- Channel geometry and wall thickness

- Filter depth (thickness)

- Face velocity (airflow rate per filter area)

Honeycomb structures are often selected because they can provide relatively low resistance compared with deeper packed beds, which helps reduce fan energy and improves system stability. But it is important to separate “system resistance” from “adsorption effectiveness.”

(cr.) According to the ASHRAE Handbook (HVAC Applications) – Air Cleaners for Gaseous Contaminants , gas-phase adsorption is defined as the attraction of contaminants to both outer and inner pore surfaces of adsorbent media, indicating that adsorption performance depends on media behavior and operating conditions—not on pressure drop alone.

2. Why Very Low Pressure Drop Can Reduce Adsorption Efficiency

A very low pressure drop often indicates one or more of the following design outcomes:

- Larger channel openings (reduced flow resistance)

- Lower carbon loading per unit volume

- Shorter residence time through the filter depth

In adsorption-driven processes, residence time and mass transfer matter. If air moves too quickly, target molecules may not sufficiently diffuse from the bulk airflow into boundary layers and then into the internal pore structure where adsorption actually occurs.

(cr.) Standard adsorption engineering references emphasize that adsorption system performance is governed by both equilibrium and kinetics. When mass transfer becomes limiting, “good adsorbent” alone cannot prevent early breakthrough under unsuitable airflow conditions.

3. Face Velocity, Contact Time, and Breakthrough Risk

Face velocity directly influences both pressure drop and adsorption behavior. In many real installations, the same filter will show different performance depending on airflow rate.

| Parameter | Lower Face Velocity | Higher Face Velocity |

|---|---|---|

| Pressure Drop | Lower | Higher |

| Contact Time | Longer | Shorter |

| Pore Utilization | Higher | Lower |

| Breakthrough Risk | Lower | Higher |

If a honeycomb filter is optimized only for “lowest possible resistance,” it may be operated at airflow conditions that compromise adsorption kinetics, causing early breakthrough and reduced service life.

(cr.) See Ruthven, Principles of Adsorption and Adsorption Processes (Wiley) for foundational discussions of adsorption kinetics, mass transfer, and how operating velocity can influence bed utilization and breakthrough behavior.

4. Pressure Drop vs Carbon Utilization (Why Service Life May Shorten)

Another engineering misunderstanding is assuming that low pressure drop automatically means “better design.” In reality, extremely low resistance designs can also correlate with:

- Lower media mass per filter (less adsorbent available)

- Reduced depth or reduced effective adsorption path

- Higher bypass sensitivity if sealing and installation are imperfect

These factors can reduce total adsorption capacity per filter and shorten replacement intervals. From a lifecycle cost perspective, a slightly higher—but controlled—pressure drop can enable better adsorption stability and lower total cost of ownership.

(cr.) The U.S. EPA notes that adsorption removes pollutants by transferring them from the air stream to the solid surface of an adsorbent, and that the adsorbent has a finite capacity—once saturated, it becomes ineffective.

(cr.) Source: EPA – Monitoring by Control Technique: Activated Carbon Adsorber .

5. What Should Be Optimized in Real Projects

In practical industrial gas-phase filtration, the goal is not “minimum pressure drop,” but balanced system performance:

- Acceptable resistance within fan capability

- Sufficient residence time for target compounds

- Stable breakthrough behavior and predictable maintenance cycles

- Compatibility with duct design and operating conditions

Honeycomb activated carbon filters should therefore be engineered for application-specific airflow conditions rather than generalized resistance targets.

6. Application-Driven Design Priorities

Different applications require different performance priorities:

- High-flow exhaust systems: controlled pressure drop with adequate depth to maintain contact time

- Low concentration “polishing”: maximizing pore utilization and residence time for trace contaminants

- Odor control / mixed VOCs: balancing airflow stability with adsorption kinetics and replacement planning

That is why a single pressure-drop value cannot define filter suitability or “efficiency” on its own.

Conclusion

Pressure drop is a critical engineering parameter, but it should not be treated as a standalone indicator of adsorption performance. In honeycomb activated carbon filters, excessively low resistance can undermine contact time and carbon utilization, leading to earlier breakthrough. A well-designed filter balances airflow resistance with adsorption kinetics to deliver stable performance across the intended service life.

Article Keywords: honeycomb activated carbon filter, pressure drop, adsorption performance, face velocity, gas phase filtration, VOC control, industrial air filtration, adsorption kinetics, breakthrough time, carbon utilization