In recent years, the global movement toward carbon neutrality has reshaped how industries design and operate air purification systems. From automotive painting lines to semiconductor cleanrooms, companies are seeking filtration materials that not only remove harmful gases and odors effectively – but also reduce their environmental footprint.

Among all available options, honeycomb activated carbon stands out as a sustainable, high-efficiency solution that bridges environmental responsibility with engineering performance.

🌍 1. The Push Toward Low-Carbon Air Filtration

Governments worldwide are tightening emission standards on volatile organic compounds (VOCs), ammonia, and sulfur-based gases. The European Union’s VOC Directive, China’s GB37822-2019, and similar U.S. EPA regulations have accelerated the demand for cleaner, more energy-efficient air treatment technologies.

Traditional granular carbon filters, while effective, often suffer from high pressure drop and frequent replacement cycles – leading to more energy consumption and waste.

Honeycomb activated carbon addresses these issues through its structured geometry, which offers:

- Low airflow resistance → reduced fan energy consumption

- High contact efficiency → better adsorption with less material

- Longer service life → fewer replacements and lower carbon footprint

🔋 2. Energy Efficiency Through Structural Innovation

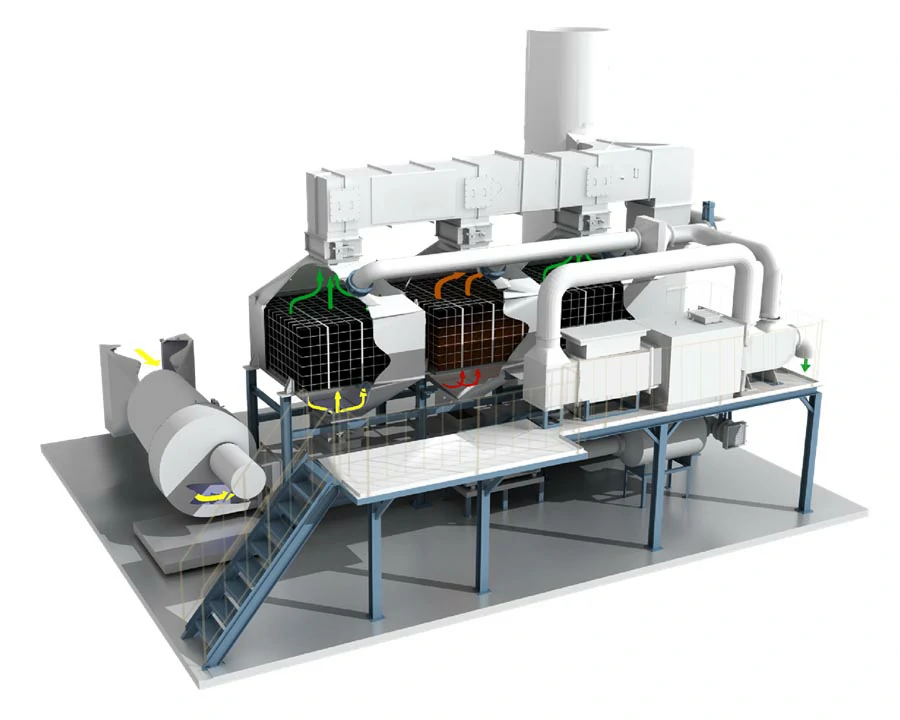

The unique honeycomb design creates a network of parallel channels that enable smooth airflow distribution. This allows for lower system pressure and consistent gas contact, translating into measurable energy savings during continuous operation.

Compared with traditional packed-bed systems, honeycomb activated carbon can reduce energy use by up to 30% in industrial ventilation lines. Moreover, the modular design simplifies installation and regeneration, making it ideal for closed-loop, sustainable operations.

♻️ 3. Recyclability and Regeneration: Circular Carbon Use

Beyond filtration efficiency, sustainability also depends on the reuse and recovery of carbon materials. Modern regeneration technologies – such as thermal reactivation or chemical oxidation – allow spent honeycomb activated carbon blocks to be reactivated multiple times without significant loss of adsorption capacity.

This closed-loop approach greatly reduces the amount of waste generated while minimizing the environmental impact of air purification systems.

At HANYAN, our research teams continuously improve the reactivation stability and surface chemistry of honeycomb activated carbon, ensuring both high adsorption performance and extended service life.

🌱 4. Aligning with Global Carbon-Neutral Strategies

As industries transition toward greener manufacturing, the use of sustainable filtration materials becomes an integral part of their ESG (Environmental, Social, and Governance) frameworks.

Honeycomb activated carbon helps companies meet their emission targets by:

- Lowering operational energy consumption

- Reducing waste through reactivation cycles

- Supporting eco-friendly manufacturing processes

By adopting such solutions, companies move closer to achieving carbon neutrality while maintaining air quality compliance and system reliability.

⚙️ 5. HANYAN’s Commitment to a Cleaner Future

As a specialized, refined, featured and original “Little Giant” enterprise in China’s activated carbon industry, HANYAN is committed to integrating innovation with environmental responsibility.

Our honeycomb activated carbon products are designed for long-lasting performance, sustainability, and compliance with international air quality standards.

From material engineering to system integration, HANYAN continues to support our partners worldwide in building a cleaner, lower-carbon future.

Conclusion

The journey toward carbon neutrality is not only about reducing emissions – it’s about optimizing every component of industrial systems. By leveraging the structural and regenerative advantages of honeycomb activated carbon, industries can significantly cut energy use, extend product life, and move toward truly sustainable air purification.

Article Keywords: honeycomb activated carbon, sustainable air filtration, carbon neutral, VOCs control, low pressure drop filter, carbon neutrality goals, eco-friendly filter, regeneration of activated carbon, ESG manufacturing, air purification system, energy efficiency, recyclable filtration material