Honeycomb activated carbon filters are widely used in air purification, gas adsorption, and odor control systems. While many factors contribute to the overall performance of these filters – such as carbon type, cell size, and impregnation – wall thickness is a critical yet often overlooked parameter that directly impacts efficiency, pressure drop, and filter lifespan.

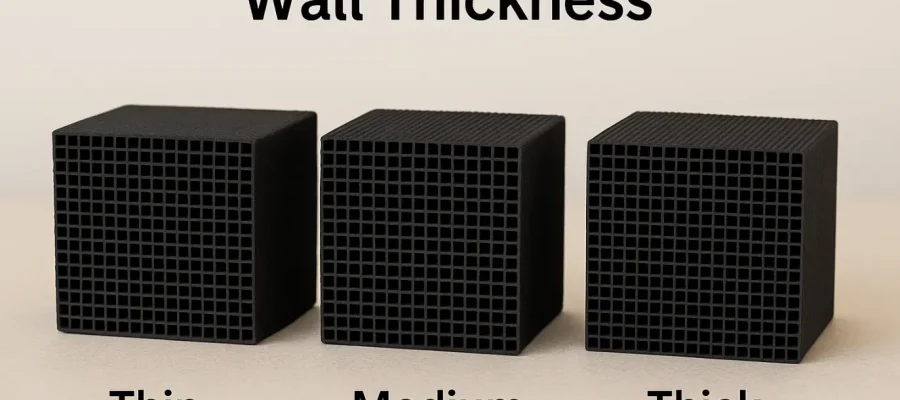

What Is Wall Thickness in Honeycomb Filters?

In honeycomb activated carbon structures, wall thickness refers to the thickness of the partition walls that separate each cell or channel. These walls are impregnated with or made entirely from activated carbon and serve as the functional surfaces for adsorption.

The wall thickness is usually measured in millimeters (mm), and most industrial honeycomb carbon filters are manufactured with wall thicknesses ranging from 0.4 mm to 1.2 mm, depending on application requirements.

Why Wall Thickness Matters

1. Adsorption Efficiency

Thicker walls contain more activated carbon mass, which increases the available surface area and total adsorption capacity. However, beyond a certain point, excessively thick walls can reduce open frontal area (OFA) and airflow efficiency.

2. Pressure Drop

A thinner wall provides a higher open area, reducing resistance to airflow and maintaining lower pressure drops. For HVAC and ventilation systems, maintaining an optimal pressure drop is essential to reduce energy consumption.

3. Mechanical Strength

In applications where vibration, temperature fluctuation, or air surges occur, thicker walls offer better structural durability. This is especially important in industrial environments or transport-related filtration systems.

4. Service Life

The service life of a honeycomb carbon filter is tied to how much pollutant it can adsorb before saturation. Thicker walls often mean longer lifespan due to increased carbon volume, but must be balanced against pressure drop and cost.

Typical Wall Thickness Ranges by Application

| Application Type | Recommended Wall Thickness |

|---|---|

| Residential Air Purifiers | 0.4 – 0.6 mm |

| Commercial HVAC Systems | 0.6 – 0.9 mm |

| Industrial Gas Filtration | 0.8 – 1.2 mm |

| Automotive Cabin Filters | 0.5 – 0.7 mm |

How to Choose the Right Wall Thickness

Choosing the right wall thickness involves evaluating several factors:

- Airflow rate: High-flow systems benefit from thinner walls to minimize resistance.

- Target gases: For low-concentration gases, thinner walls may suffice; high-concentration gases require more carbon mass.

- Filter dimensions: Larger filters can handle thicker walls without excessive pressure drop.

- Budget constraints: Thicker walls increase material cost, so optimal balance is necessary.

Tip: If you’re unsure, start with a mid-range thickness (e.g., 0.8 mm) and request sample testing under your specific operating conditions.

Conclusion

Wall thickness is not just a mechanical parameter – it’s a performance-critical variable in the design of honeycomb activated carbon filters. Selecting the appropriate thickness can significantly impact adsorption efficiency, system energy consumption, and long-term maintenance costs. Whether you’re customizing for an OEM project or choosing a standard size, understanding wall thickness is key to engineering the right solution.

Article Keywords: wall thickness, honeycomb activated carbon, activated carbon filter design, filter lifespan, pressure drop, OEM carbon filters, airflow resistance