OEM partners worldwide are seeking tailor-made honeycomb activated carbon filters to meet stringent requirements in environmental protection, air purification, and chemical gas removal. As an industry-leading manufacturer, HANYAN offers full customization solutions, backed by in-house R&D, automated production lines, and extensive project experience.

Why Choose Honeycomb Activated Carbon for OEM Projects?

Compared to traditional granular or pellet activated carbon, honeycomb activated carbon offers:

- High surface area-to-volume ratio

- Low pressure drop and uniform airflow

- Excellent VOC and odor adsorption performance

- Clean structure with no dust shedding

- Lightweight and stackable design for modular systems

What Can Be Customized?

We offer extensive customization options to meet diverse industry applications, such as air filtration, gas-phase adsorption, and cabin air treatment. Customizable parameters include:

- Dimensions: Length × Width × Thickness, in mm or inches

- CPSI (Cells Per Square Inch): From 25 to 400 CPSI

- Activated Carbon Type: Coconut shell, coal-based, wood-based, or impregnated

- Activation Process: Steam activation, chemical activation, secondary activation

- Impregnation Options: KMnO₄, HCL, NaOH, KOH, or customized chemical agents

- Coating & Housing: Plastic, aluminum, or galvanized frames (optional)

- Packaging: OEM branded cartons, vacuum bags, or palletized bulk

Industries We Serve

Our OEM solutions are trusted in projects across the following sectors:

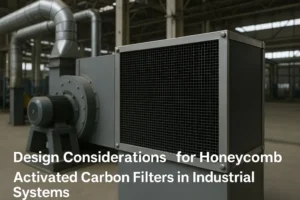

- Industrial VOCs removal systems

- Automotive and rail cabin air filtration

- Medical and laboratory fume extraction

- Consumer-grade air purifiers

- Semiconductor and precision manufacturing exhaust treatment

From Design to Delivery: One-Stop OEM Service

At HANYAN, we streamline the entire OEM process for your honeycomb activated carbon filter needs:

- Initial Consultation: Engineering team gathers technical specs and project requirements.

- Sample Prototyping: Sampling based on customer’s CAD design + pilot production with lab testing support.

- Performance Matching: Iodine value, CTC, or other tests available.

- Mass Production: Automated extrusion lines and strict QC inspection.

- Custom Packaging: Carton design(if needed), private label, and export-ready solutions.

Why Work with HANYAN?

- Over 10 years of honeycomb activated carbon production experience

- Independent R&D center with more than 200 patented technologies

- Full ISO, REACH, and ROHS compliance

- Support for UL-900, JIS, and other third-party testing

- Factory-direct pricing with no middleman markup

Need a Custom Honeycomb Carbon Filter? Contact Us!

Ready to get started on your OEM project? We’re here to assist with technical guidance, sample development, and fast-track production.

Article Keywords: custom honeycomb activated carbon, OEM carbon filter, honeycomb carbon manufacturer, VOC removal filter, CPSI carbon, activated carbon customization, carbon filter OEM supplier