In the modern era, the production of small home appliances has become an indispensable part of our daily lives. However, the surge in manufacturing has also led to the emission of exhaust gases, posing environmental challenges. Addressing this issue requires innovative and sustainable solutions, one promising method involves the use of activated carbon.

Understanding Emissions from Small Appliance Factories

Small appliance factories contribute to convenience and comfort to people while typically emitting exhaust gases during manufacturing processes. These gases may contain volatile organic compounds (VOCs), toxic fumes, or other harmful substances. Without proper treatment, these emissions can adversely affect human health and the environment.

The Role of Activated Carbon

Activated carbon is a highly porous material with a large surface area, known for its ability to adsorb various gases and impurities. Its porous structure provides an extensive adsorption area for different molecules, effectively capturing pollutants in the air.

Applications of Activated Carbon in Gas Treatment

Adsorption process: As exhaust gases pass through an activated carbon filter, its porous structure captures pollutants, allowing clean air to pass through. This process effectively removes VOCs, odors, and other contaminants.

Customization and efficiency: Activated carbon can be customized for specific applications by altering its pore size, surface area, and chemical properties. This customization enhances its efficiency in adsorbing specific gases emitted from different appliance manufacturing processes.

Regeneration and reuse: A significant advantage of activated carbon is its regenerative capacity. Once it reaches its adsorption capacity, the carbon can be regenerated through thermal or chemical treatment, restoring its adsorptive properties for reuse, thereby reducing waste.

The Selection of Activated Carbon

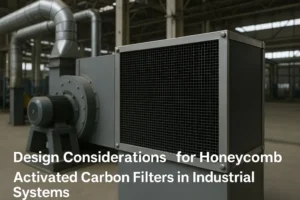

The commonly used activated carbon for waste gas treatment in small appliance factories are coal-based activated carbon and honeycomb activated carbon. The generally used of coal activated carbon is 4mm pellet activated carbon and 8×30 mesh granular activated carbon, while the generally used of honeycomb activated carbon is 100x100x100mm lump activated carbon. After correctly used, both activated carbon can effectively remove the exhaust gas and meet the required emission standard. If you want to know how to effectively select activated carbon for VOCs waste gas treatment, please click on How to Choose High-Quality Activated Carbon for Efficient VOCs Treatment

Implementing Activated Carbon Technology

Implementing activated carbon adsorption technology in a small appliance factory involves several steps:

Assessment and customization: Understanding emissions and customizing the activated carbon adsorption system.

Installation of treatment units: Integrating activated carbon filters or adsorption units into the production line to effectively handle exhaust gases.

Monitoring and maintenance: Regularly monitoring the system’s performance and maintenance to ensure optimal efficiency and longevity.

Environmental and Economic Benefits

Reducing environmental impact: Activated carbon treatment can significantly reduce harmful emissions, protecting people from air pollution and reducing impacts on surrounding ecosystems and communities.

Compliance with emission standards: By implementing effective gas treatment measures, factories can comply with emission regulations, ensuring sustainable and responsible production practices.

Cost-effectiveness: Though the initial setup cost may be a consideration, the long-term benefits, including reduced emissions and potential reuse of activated carbon, can save costs over time. Cheap upfront doesn’t mean cheapest down the road, factories should think more about overall costs.

Summary

The application of activated carbon in treating emissions from small appliance factories demonstrates a sustainable method to alleviating environmental issues associated with manufacturing processes. As technology advances, further research to enhance the efficiency of activated carbon and explore alternative adsorbents can pave the way for more effective gas treatment methods. In summary, the use of activated carbon is a brilliant way in addressing the challenges of emissions from small appliance factories. By adopting innovative solutions and sustainable practices, these factories can not only reduce their environmental impact but also contribute positively to cleaner air.